HLSG mndandanda Kusakaniza Granulator

Mfundo yogwira ntchito

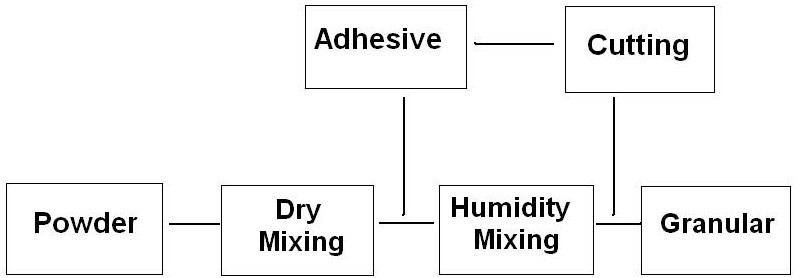

* Njirayi imakhala ndi mapulogalamu awiri kuphatikiza kusakaniza ndi granulating.

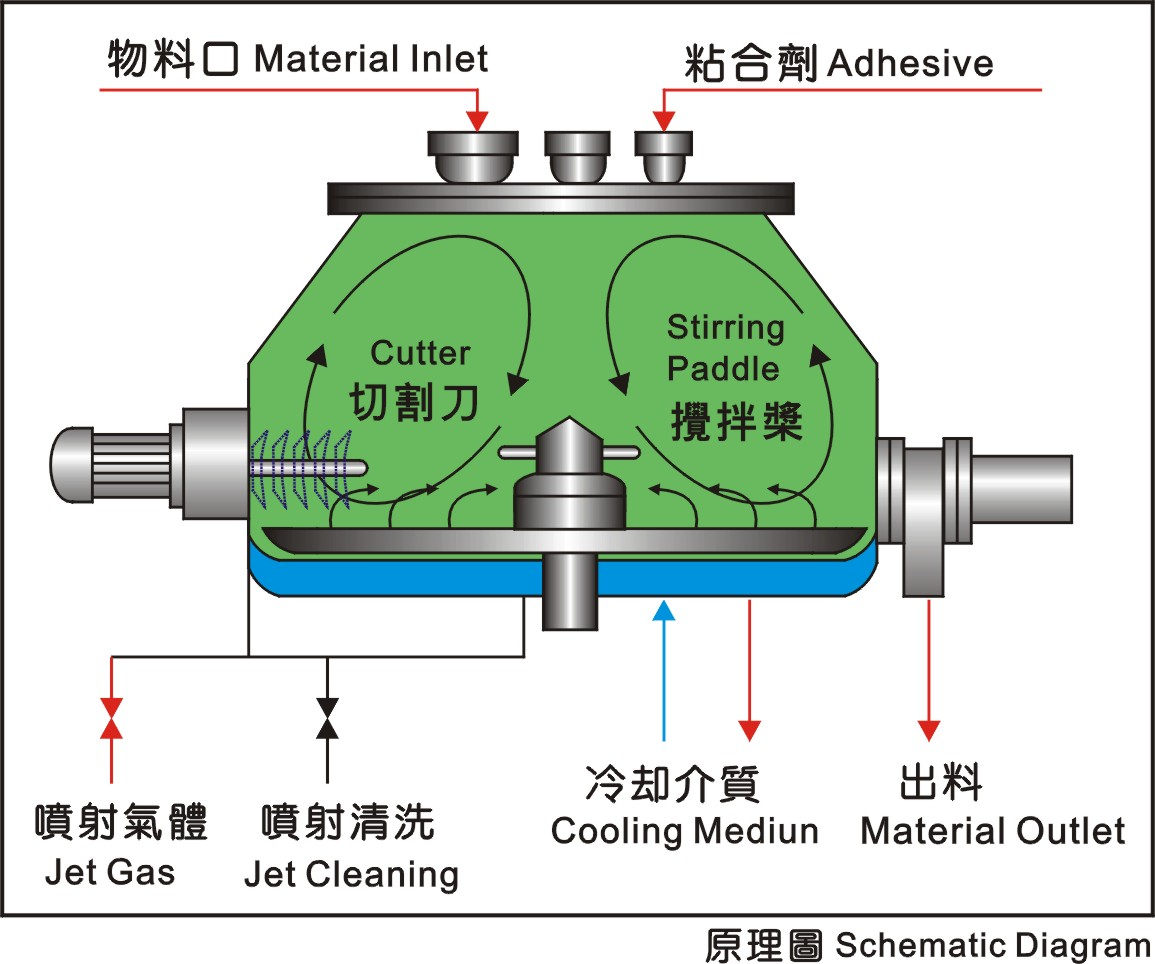

* Zinthu zaufa zitha kuyikidwa mu chiwaya chachitsulo kuchokera ku conical hopper ndikupitilira kuzungulira mu chidebe ndikusakaniza tsamba chitsekerero chikatsekedwa.Pakali pano, zipangizo zonse kukula mawonekedwe a madzi mlatho pansi mosalekeza zotsatira za conical khoma.Pogwiritsa ntchito extrusion, mikangano komanso crumb ndi tsamba ndi conical thanki khoma, zinthu zonse zimatembenukira pang'onopang'ono.

kumasula.Pamapeto pake, potsegula potulutsa hopper, tinthu tating'ono tamadzi timakankhidwa pansi pa tsamba la centrifugal zotsatira.

* Izi zofewa particles amapangidwa osati kudalira anakakamizika extrusion zotsatira, ndendende, makamaka ang'onoang'ono ndi yunifolomu particles amapangidwa pambuyo mosalekeza kudula pansi yaing'ono-zamadzimadzi boma.Pazonse, makinawa amatha kuzindikira kusinthana pakati pa zida zosiyanasiyana.

Makhalidwe

● Ndi teknoloji yokhazikika yopangidwa ndi makina ( man-machine interface ngati njira yosankhidwa ), makinawo amatha kutsimikiziridwa kuti ali okhazikika pamtundu wabwino, komanso ntchito yosavuta yogwiritsira ntchito pamanja kuti ikhale yosavuta kugwiritsa ntchito tekinoloje ndi kupita patsogolo.

● Atengere pafupipafupi liwiro kusintha kulamulira yogwira tsamba ndi wodula, zosavuta kulamulira kukula kwa tinthu.

● Ndi shaft yozungulira yodzazidwa ndi mpweya, imatha kuteteza fumbi lonse kuti lisapangike.

● Ndi kapangidwe ka thanki ya conical hopper, zinthu zonse zimatha kukhala mozungulira.Thankiyi imayikidwa ndi cholumikizira pansi, momwe madzi ozizira amazungulira omwe ali ndi magwiridwe antchito apamwamba kuposa oziziritsira mpweya, zomwe zimapangitsa kuti tinthu ting'onoting'ono ting'onoting'ono.

● Ndi chivundikiro cha poto chodzikweza chokha, chotengera cha thanki chikugwirizana ndi chowumitsira, makwerero odzipangira okha, ndikosavuta kugwiritsa ntchito.

● Makina onyamulira ndi chopalasira amapindulitsa kwambiri kuyeretsa zopalasa ndi mapoto.

● Kukamwa kwa zinthu zakunja kwasintha kukhala kooneka ngati arc, kupeŵa malo akufa.

Magawo aukadaulo

| Chitsanzo | HLSG-50 | Chithunzi cha HLSG-100 | HLSG-200 | HLSG-300 | |

| HopperVoliyumu | 50L | 100l pa | 200L | 300L | |

| Zogwira mtimaKugwira ntchitoMphamvu: Zakuthupi gawo 0.5 g/cu.cm | 12-35L | 25-80L | 60-160L | 80-240L | |

| nthawi ya ntchito | Kusakaniza: pafupifupi 2 mins Granulating: pafupifupi7-14 min/batch | ||||

| Granularity | φ0.14-φ1.5mm(12 - 100mesh) | ||||

| Kusakaniza Motor | 5.5KW6Pole | 7.5KW 6 Pole | 15KW 6Pole | 22Kw 6 Pa | |

| Tembenukirani Kuthamanga kwa Paddle Paddle Liwiro losintha pafupipafupi | 30-380R/mphindi | 30-250R/mphindi | 30-250R/mphindi | 20-200R/mphindi | |

| Granulating Motor | 1.5KW 2 Pole | 3KW 2 Pole | 4KW 2 Pole | 7.5KW 2 Pole | |

| Sinthani Kuthamanga kwa Granulating Paddle Liwiro losintha pafupipafupi | 50-3000R/mphindi | ||||

| Air Compress | 0.3 stereo/mphindi 0.7Mpa (yokhala ndi wogwiritsa ntchito.) | ||||

| Mgwirizano wa Madzi Ozizirira | Φ10mm | ||||

| Mgwirizano wa Air Compress | φ10mm | ||||

| Kutalika kwa Charger Outlet | 796mm | 796 mm | 920 mm | 985mm | |

| Makulidwe Onse (L ×W×H)mm | 1935×662×1575 | 2078× 702 × 1720 | 2180×810 × 2100 | 2420x970x2 pa450 | |

| Kulemera | 400kg | 700kg | 1100kg pa | 1350kg | |